Hot-air test rig with water injection

The hot-air test rig at the Chair of Fluidics is used for investigation into the operational behavior of different types of expanders based on the open Joule cycle. Thereby, the focus is set on the investigation of screw-type expanders.

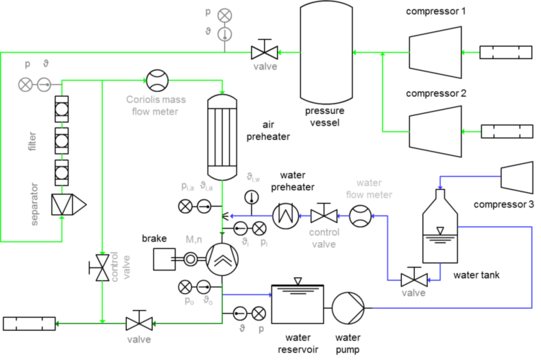

The test rig consists of a water-flooded screw compressor unit, pressure vessel, filter unit, electrical preheater, an eddy current brake, and electrically controlled valves for constant operating conditions. Furthermore different measurement instruments are embedded to monitor pressure, temperature, mass flow, rotational speed, and driving torque at different points in the test rig. The compressor unit provides a total pressure up to 13 bar at the inlet domain of the investigated machine. In addition, a second open loop is installed to provide auxiliary fluid (water), which can be injected either into the pressurised hot-air pipe or into the investigated machine.

A more detailed description of the installed components and the measurement instruments is given below.

-

Compressor Unit

The compressor unit consists of a water-flooded screw compressor stage. The compressor draws in ambient air and the pressurised air is fed into a pressure vessel. Higher pressure levels in the inlet domain of the investigated machine can be achieved by connecting an additional compressor to the system. -

Measurement Instruments

In order to record information about the fluid state in the hot-air loop temperature and pressure measurement devices are installed in the test rig at different positions. Insulated thermocouples which can be used to monitor temperatures up to 400°C are installed. The local pressure is recorded by means of static relative pressure transducers. In terms of expander torque and rotational speed measurement, a torque metering device is used. Hot-air mass flow is recorded by means of a Coriolis mass flow meter. -

Control Equipment

For constant operating conditions, diverse controlling devices are installed in the test rig. By means of an eddy current brake and a bypass valve, a constant rotational speed and a constant pressure at the inlet domain of the investigated machine can be set. In order to set constant air inlet temperatures, an electrical preheater is installed in the hot air test rig. The preheater provides a maximum heating output power of 21 kW. -

Water Injection Loop

Auxiliary fluid (f.e. water) is injected either into the hot-air pressurised pipe in front of or into the investigated expander. The injected water can be preheated by means of a boiler up to a maximum temperature of 85°C at constant water volume flow of 7 l/min. The mass flow of the auxiliary fluid is recorded by means of a magnetic inductive mass flow meter.