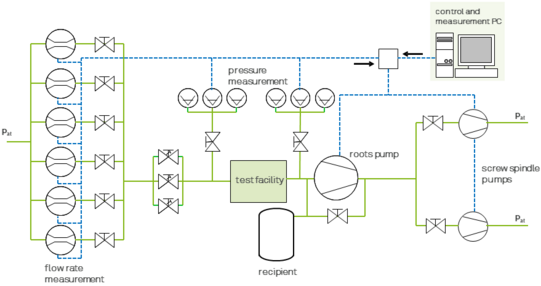

Vacuum test rig

The vacuum test rig at the Chair of Fluids at TU Dortmund University is used for the investigation of vacuum pumps and also for other different experiments in the field of vacuum technology. The investigations are focusing on the determination of characteristic diagrams of vacuum pumps. An additional application of the test rig is the training of students in experiments with rarefied gas flows.

The installed components of the test rig are amongst others two dry running screw vacuum pumps, one roots vacuum pump and also a recipient with a volume of 0.5 m². In addition, different sensors are used for the recording of pressure and mass flow. The pump system is providing a suction speed up to 800 m³/h, which can be increased by switching on the second screw vacuum pump.

Pump system

The screw vacuum pumps are used as forepumps and are working against atmospheric pressure. By reaching the ultimate pressure the suction pressure at both pumps is 10-2 mbar. A roots pump can be used for the enhancement of the ultimate pressure and suction speed. In this case the combination of pumps can reach a pressure less than 10-3 mbar. All pumps can be controlled by modifying the rotational speed by the use of frequency converters.

Sensors

For the measurement of the pressure capacitive absolute pressure sensors are used. To cover up an effective range from 10-2 mbar up to 103 mbar 5 sensors can be arranged respectively. The flow rate is measured by 7 flow meters in a range of 0,01 l/min - 200 l/min at standard conditions.

High vacuum test rig

A separate rig with a slide vane rotary vacuum pump und a molecular pump can be used for the generation of a pressure less then 10-3 mbar. This combination has a nominal suction speed of 230 l/s at a suction pressure of 10-5mbar. The high vacuum test rig can be used besides other applications, for the alignment of pressure sensors.

Support

Contribution in kind (machinery) from Oerlikon Leybold Vacuum GmbH, Sterling SIHI GmbH and Pfeiffer Vacuum