Investigation of hydraulic losses in twin-screw machines

Content

Project description - Contact person - Cooperation / Funding

Project description

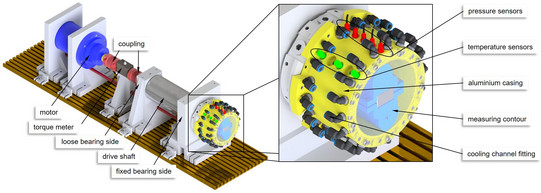

Generic experiment to investigate hydraulic loss mechanisms within the area of the housing clearance of twin-screw machines.

The generic experiment presented in Figure 1 is designed for the investigation of hydraulic loss mechanisms in screw machines. A torque metering device is installed between the motor and the drive shaft. Enclosed by a cylindrical casing made of aluminum, two measuring contours are attached to the end of the shaft.

In the detailed view, five pressure sensors (red-colored) are equidistantly distributed in the axial direction. The pressure sensors measure the static pressure inside of the cylindrical casing. Similarly, three temperature sensors (green-colored) are distributed in the axial direction. The cooling of the casing is obtained by means of 18 axial cooling in the casing. The front side of the casing is covered with transparent acrylic glass. Using a high-speed camera, the liquid distribution inside the chamber can be recorded during operation.

The experiments are carried out after filling a predetermined amount of liquid (e.g. water or oil) into the cylindrical casing through a bore in the acrylic glass cover. Then, the bore is sealed so no water can leak out of the casing. The pressure inside the housing corresponds to the atmospheric pressure. The next step is to record the torque and further variables at different speeds and circumferential speeds, respectively.

Contact person

Cooperation / Funding

This project is funded by the TU Dortmund.