SteamScrew - Development of a high temperature heat pump with twin-screw steam compressor for heat and process steam generation

Content

Project description - Contact person - Cooperation / Funding

Project description

Joint project: SteamScrew - Development of a high temperature heat pump with twin-screw steam compressor for heat and process steam generation

Sub project: Theoretical and experimental investigation of twin-screw steam compressors

Goal of the project SteamScrew is the development of a high temperature heat pump with a twin-screw steam compressor. The source temperature of the heat pump is between 80 und 120°C, whereas the heat sink temperature is up to 200°C. Overall goal is to decarbonise industrial heat supply in energy-intensive industries, which is often achieved using conventionally driven CHP.

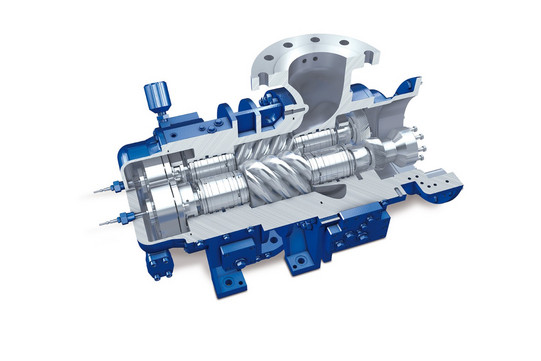

The use of water as refrigerant is technically challenging, because steam undergoes a strong temperature increase during its compression. Therefore, an oil-free screw compressor with water injection is used as the compressor, which is developed based on proven compressor concepts. This machine design is suitable for realizing the required rise in pressure and temperature in a single stage.

After experimental investigation of the heat pump system, it is possible to scale up the system to the megawatt range for industrial application. In perspective, this should establish an environmentally friendly heat pump for decarbonization of industrial heat supply.

Contact person

Cooperation / Funding

This project is funded by the Federal Ministry for Economic Affairs and Climate Action. It is carried out in cooperation with the Fraunhofer Research Institution for Energy Infrastructures and Geothermal Systems IEG and Aerzener Maschinenfabrik GmbH.